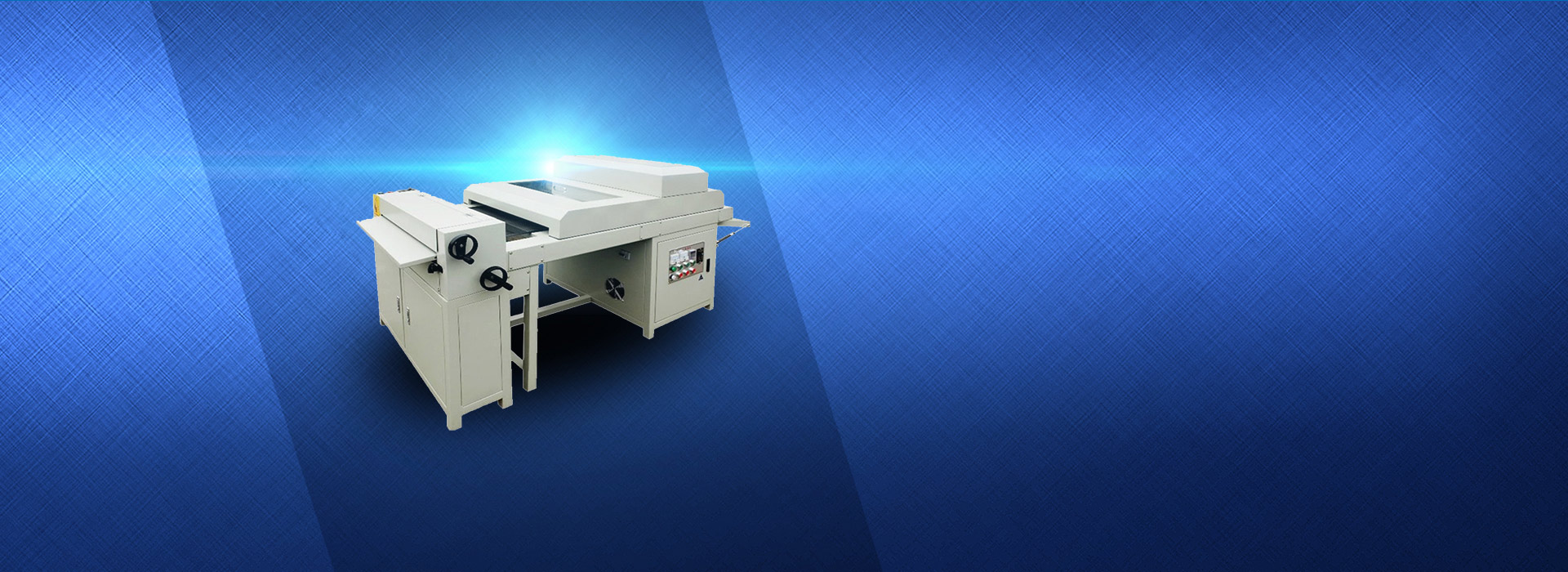

Total Power | 8KW |

Overall Size | 4100*800*1600mm |

Free Speed | 15-23m/min |

Edge Thickness | 0.3-3mm |

Panel Thickness | 8-60mm |

Panel Length | ≥150mm |

Panel Width | ≥60mm |

Working Pressure | 8Kg |

Min.Panel Size | 50mm |

Weight | 740Kgs |

1.Per-milling---Trim equipment with double trim blades works on the waved effect that is caused by precise saw.

2.Gluing---Glue mechanism adopts a special structure to gelatinize the plated and coat materials uniformly, which ensures a more solid conglutination.

3.End trimming---End trimming mechanism through a precise guide track movement, adopts automatic tracking and high frequency motor fast cutting structure to ensure the cutting surface smoothly.

4.Rough and Fine Trimming---Rough/Fine trimming mechanism is used for repairing the excess edge materials, adopting automatic tracking and high frequency motor fast cutting structure to ensure the trimming plates smoothly.

5.Conner trimming---Profiling unit is to make board end more smooth and aesthetic.

6.Scraping---Scraping unit works for a perfect finishing of the applied edge.

7.Buffing--- Buffing device adopt the board processed by cotton polishing wheel, by end-polishing to make a more smooth surface.

中文

中文 English

English